Pressure and Temperature Tables According to Material Properties

ASTM A 216 Gr WCB Material Group 1.1: Carbon steel used in all valves for regular and general use. Not recommended for temperature conditions above 425C. ASTM A 217 Gr WC1 Material Group 1.5: Carbon, known as 1/2 Molybdenum steel. It is a low carbon, high temperature steel, resistant to temperatures up to 455C, suitable for joining by welding. ASTM A 216 Gr

ASTM A 216 Gr WCB

Material Group 1.1: Carbon steel used in all valves for regular and general use. Not recommended for temperature conditions above 425C.

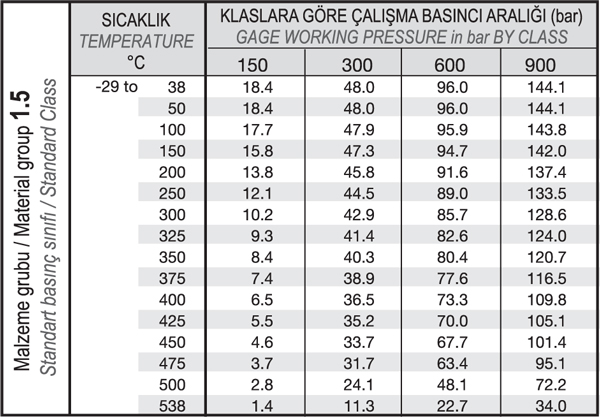

ASTM A 217 Gr WC1

Material Group 1.5: Carbon, known as 1/2 Molybdenum steel. It is a low carbon, high temperature steel, resistant to temperatures up to 455C, suitable for joining by welding.

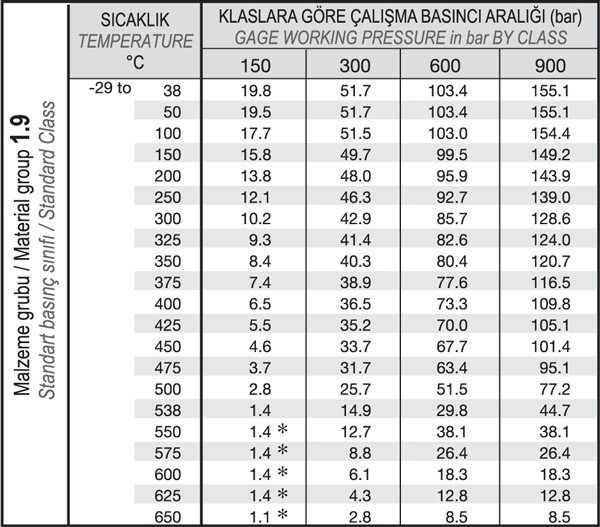

ASTM A 216 Gr WC6

Material Group 1.9: 1 1/4 Chrome, 1/2 Molybdenum steel. Suitable for temperature conditions up to 593C.

* For weld end valves only. Up to 538C for flanged.

ASTM A 216 Gr WC9

Material Group 1.10: Known as 2 1/4 Chrome, 1 Molybdenum steel. Suitable for temperature conditions up to 593C.

* For weld end valves only. Up to 538C for flanged.

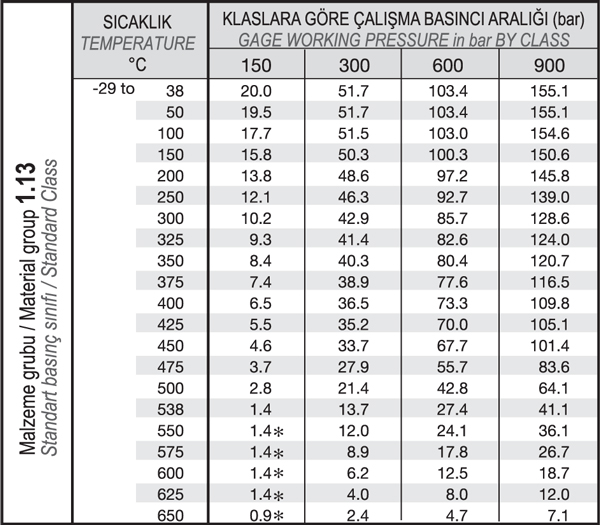

ASTM A 217 Gr C5

Material Group 1.13: 5 Chrome, 1/2 Molybdenum steel. Used in high pressure and temperature conditions. Suitable for corrosive environments. It is a difficult material group to assemble by welding.

ASTM A 351 Gr CF8

Material Group 2.1: Austenitic stainless steel containing 18-21 Chromium, 8-11 Nickel. Suitable for many corrosive fluid environments.

* For weld end valves only. Up to 538C for flanged valves.

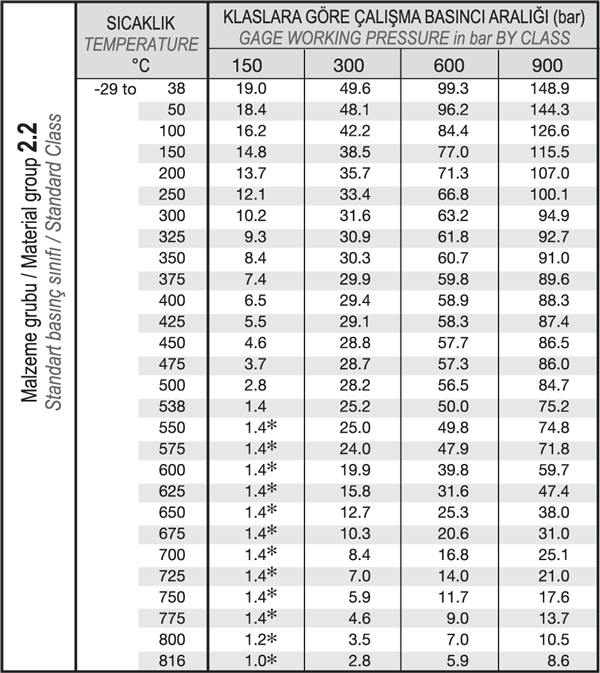

ASTM A 351 Gr CF8M

Material Group 2.2: Austenitic stainless steel containing 18-21 Chromium, 8-11 Nickel, 2-3 Molybdenum. It is suitable for situations requiring high corrosion resistance, where 18-8 austenitic stainless steels are generally used.

* For weld end valves only. Up to 538C for flanged.